Manufacturing & OSHA: What to Know Before an Inspection

Table of Contents

When you’re managing safety protocols for a manufacturing facility, you’re actively checking that everything is up to date. You’re reviewing last year’s emergency plan, gathering reports, testing new systems, all with one goal in mind: keeping employees safe and minimizing costly disruptions.

But with so many moving parts, it’s easy to overlook the small details… the same ones that could lead to costly OSHA fines.

We know manufacturing and OSHA go hand-in-hand, and we also know how expensive those fines can be. That’s why we wrote this blog to give you everything you need to know to stay compliant, avoid violations, and prepare your facility for an OSHA inspection, specifically from a manufacturing perspective.

Stratus-io: Emergency Management

How Manufacturing and OSHA Are Connected

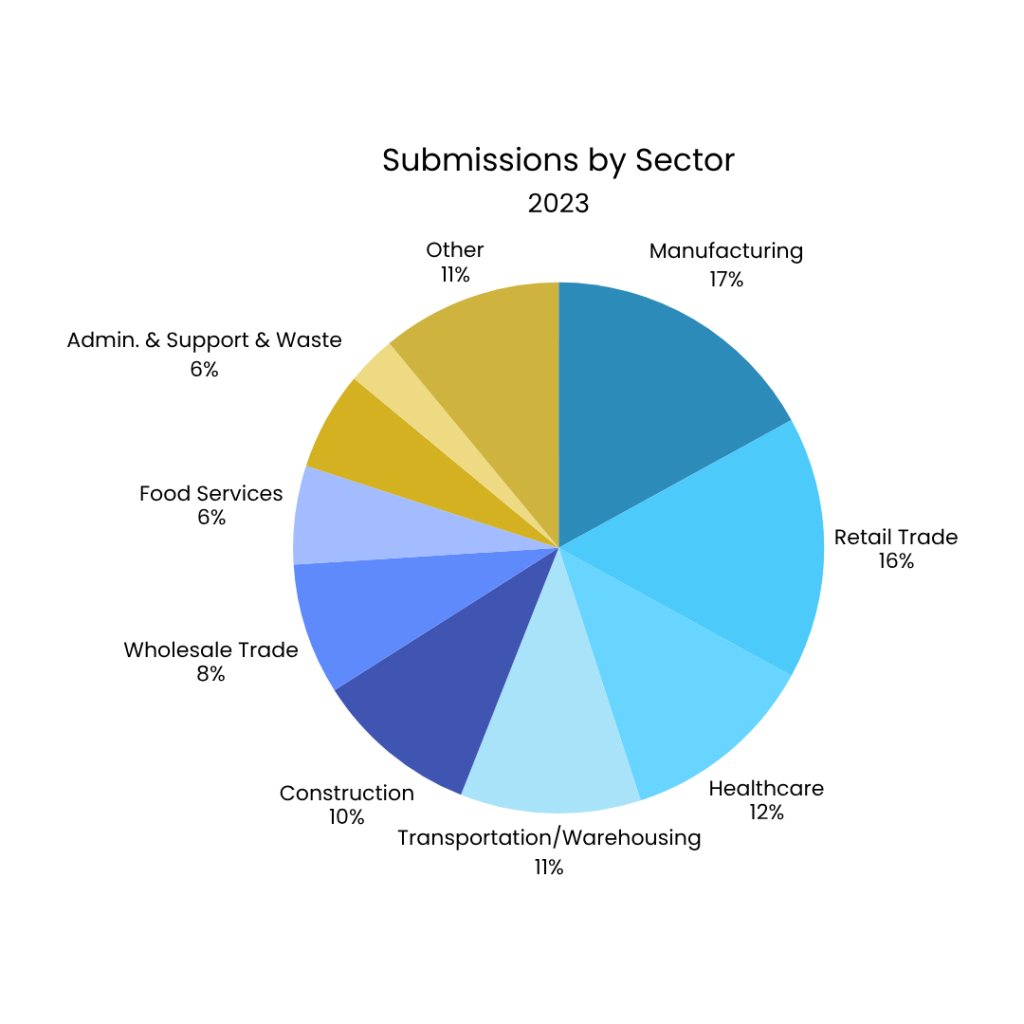

Since its establishment in 1970, the Occupational Safety and Health Administration (OSHA) has transformed workplace safety standards across the United States. Today, companies in every industry invest in safety managers, training programs, and preventive measures to build a strong safety culture and protect their teams. But manufacturing remains under the most scrutiny, and for good reason. On May 31, 2024, OSHA reported receiving over 385,000 submissions summarizing work-related injuries and illnesses. Nearly two-thirds of those came from just five sectors, with manufacturing leading the list. This means manufacturing facilities face a higher likelihood of inspections and, if unprepared, costly violations.

A Real OSHA Violation That Cost Thousands

You’ve probably read headlines about OSHA violations or overheard stories from other plant managers. Maybe you’ve even thought, “That won’t happen here.” But it hits differently when you see the numbers, and realize it could.

In October 2023, Cavco Industries Inc., a modular and manufactured home producer, was hit with $272,479 in penalties after an OSHA inspection uncovered more than two dozen serious safety and health violations. Investigators found hazards ranging from a lack of fall protection and unsafe ladders to improperly inspected fire extinguishers and missing personal protective equipment.

For Cavco, the inspection wasn’t just a slap on the wrist, it was a costly wake-up call. And while the details might sound extreme, the reality is that many of these violations stem from everyday oversights that any facility could fall into if safety standards slip.

Comply Today. Avoid Fines Tomorrow.

Whether you manage a small plant or a large manufacturing facility our software tailors to your needs so you can pass your OSHA inspection with confidence.

Manufacturing and OSHA: What to Know Before an Inspection

OSHA isn’t just about paperwork and checklists, it’s about keeping people safe. Yes, compliance can feel like a lot, but the cost of ignoring it (both financially and human-wise) is far higher. Luckily, there are plenty of ways to make inspections less stressful and avoid OSHA fines.

Here are some key areas inspectors often look for in manufacturing facilities:

1. Machine Guarding

Designed to keep workers safe from moving parts, sparks, or flying debris. If you’ve got new equipment, make sure training happens before someone gets too close. And no, a piece of cardboard zip-tied to the side doesn’t count.

2. Lockout/Tagout (LOTO):

This procedure ensures machines are powered down and locked before maintenance. You’d be surprised how often people accidentally leave the key in, and yes, OSHA will notice. It’s more common than you think, and it’s exactly why this safety regulation exists.

3. Injury Reporting

4. Respiratory Protection

Millions of workers in manufacturing wear respirators to prevent cancer, lung impairment, or even death. From dust to fumes, if it’s in the air, you need the right gear and training. No one should be breathing in yesterday’s sanding project. Avoid that fine, and protect your team’s health by implementing a written respiratory program.

5. Powered Industrial Trucks

Forklifts and other industrial trucks require proper operations training, daily inspections, and immediate removal from service if unsafe. Sure, people like to personalize them with funny decorations, but OSHA cares more about whether the brakes work and the seatbelt clicks.

6. Hazard Communication

7. Walking Working Surfaces

Keep floors clean, aisles clear, and walking areas free of clutter or spills. It might seem like common sense, but blocked pathways and uneven flooring are some of OSHA’s most cited violations.

8. Hearing Conservative Program

If noise levels reach or exceed 85 decibels over an 8-hour shift, OSHA requires hearing protection and annual hearing tests. In manufacturing, loud machinery is part of the job, but hearing loss doesn’t have to be. Monitor noise levels annually, provide quality hearing protection, and make it a workplace habit.

Stay Compliant with Emergency Management Software

So, you’ve checked the respirators, updated the injury logs, and made sure every aisle is clear. That’s great, your facility is in good shape for today. But OSHA compliance isn’t just about passing one inspection; it’s about staying ready every single day. And in manufacturing, the ability to respond quickly can make all the difference.

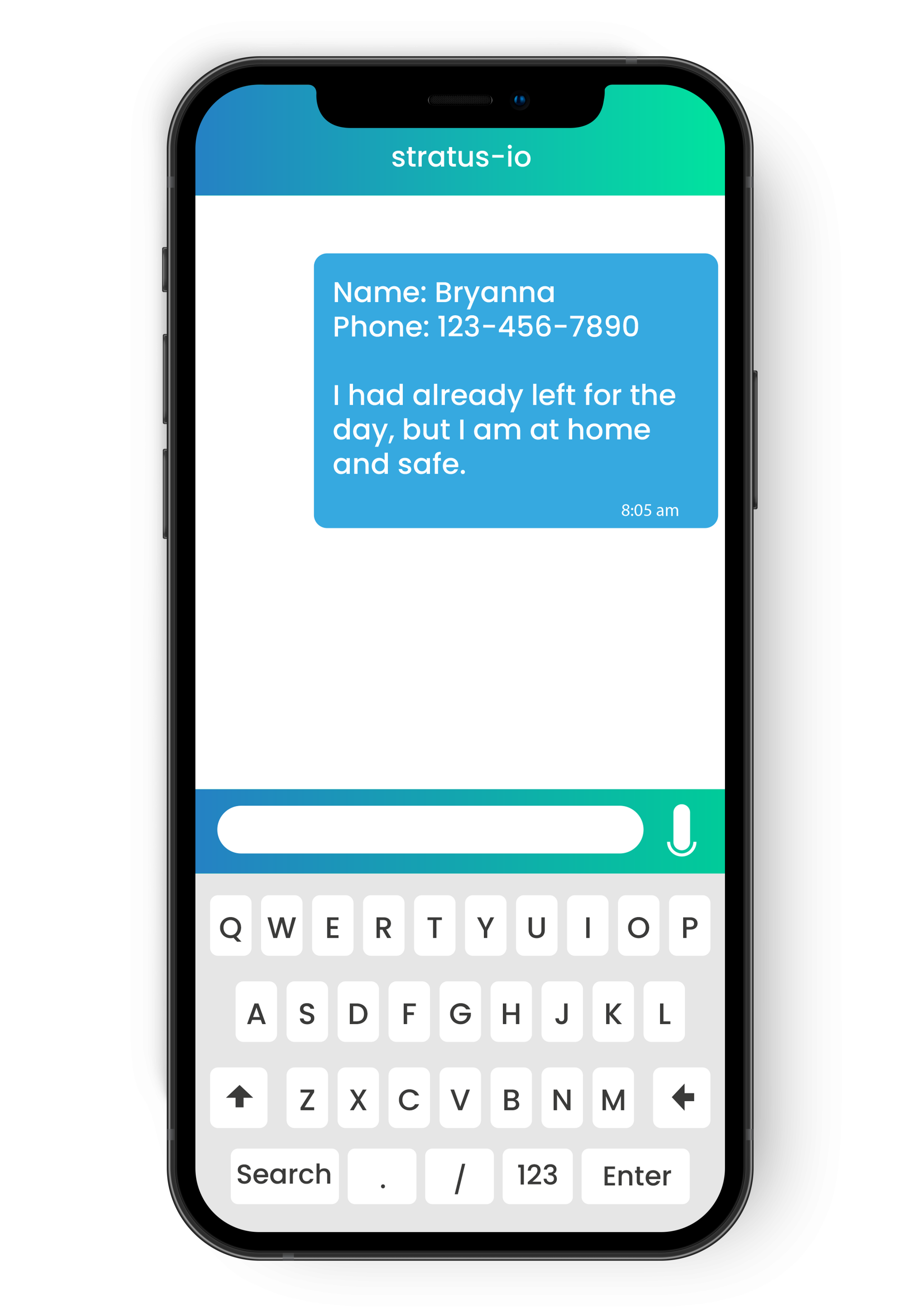

That’s where Stratus-io: Emergency Headcount comes in. This emergency management software helps manufacturing facilities streamline safety protocols, enhance communication, and reduce stress during high-pressure situations.

Here are a few ways it can keep you one step ahead:

-

Access Control

If a forklift is out of service or a hazardous area needs to be restricted, you can control who can enter specific rooms or zones, preventing accidents before they happen.

-

Attendance Tracking

Imagine a sudden machine malfunction causes a fire in one section of your plant. Instead of scrambling to count employees on paper, you can instantly see who has checked in, who’s missing, and where they were last located.

-

SMS Notifications

Need to alert staff about mandatory training for a new piece of equipment or a safety hazard that just popped up? Send instant text alerts to every employee in seconds.

-

Geofence

If your company operates across multiple facilities or large campuses, geofencing ensures that only the employees in the affected area receive evacuation alerts, keeping communication relevant and efficient.

-

Data Reports

After an incident or drill, pull detailed reports showing who was present, who evacuated, and who didn’t. This makes compliance reporting easier and helps identify gaps in safety procedures.

In manufacturing, small oversights can lead to consequences. However, with the right tools, you can protect your people and facility.

Want to see how Stratus-io: Emergency Headcount works in action?

Watch the video below and discover how we can enhance your emergency plan!

Cloud-In-Hand® Solution Team

This blog reflects the expertise of the Cloud-In-Hand® Solution Team with over 100 years of experience in hardware, software, and firmware development. Since founding Solutions Consulting in 1992, now known as Serialio LTD, the Solution Team has designed and developed many innovative solutions. Cloud-In-Hand® Stratus-io Time and Attendance, helps organizations like Apple, Google, Toshiba, LinkedIn, Salesforce, and many more, streamlining their operations.

Cloud-In-Hand® Solution Team

This blog reflects the expertise of the Cloud-In-Hand® Solution Team with over 100 years of experience in hardware, software, and firmware development. Since founding Solutions Consulting in 1992, now known as Serialio LTD, the Solution Team has designed and developed many innovative solutions. Cloud-In-Hand® Stratus-io Time and Attendance, helps organizations like Apple, Google, Toshiba, LinkedIn, Salesforce, and many more, streamlining their operations.